- support

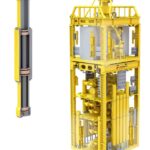

Forging High Pressure Carbon Steel Oil Drilling Bop

£54,000.00

Ram BOP

The TSC ram BOP can effectively control wellhead pressure to prevent blowout related accidents during drilling and workover operations.

Add to wishlist

Share

CategoriesAll Category, Underwater Operations

- When there is a well string, the ram BOP can be coupled with a ram assembly to seal the annual space between the casing and tubing string;

- When there is no well string, the ram BOP can be coupled with full sealing disc assembly to close the wellhead;

- When there is a tight type damper control device and the situation is urgent, the ram BOP can be coupled with a shear ram cut tubing string in the well, to seal the entire mouth of the well.

- In the event that the ram BOP has closed, sealing the well, it can be connected to the outlet side of the choke & choke manifold kill blowout to conduct well washing and other special operations.

- Upper and lower connection: the upper flange, planted wire, clamp connection; the lower flange, planted, clamp wire connection.

- Pressure (psi)2000 – 20000

- Nominal Diameter (in)7 1/16 – 30

- Working MediaOil, gas, mud, H2S and CO2 gases

- Temperature ClassT75, T20, T0

- Metal Seal Temperature LevelA-D (-15°F – 250°F)

- Rated Hydraulic Controlled Working Pressure (psi)3000

- Recommended Working Pressure (psi)1200 – 1500

- LockHydraulic and manual lock

- Fluid Containment Specifications1

- Optional RamHalf sealing gate, sealing ram, shear ram

- Outlet Side Connectionflange, silk, clamp connection

Ram BOP

Be the first to review “Forging High Pressure Carbon Steel Oil Drilling Bop” Cancel reply

Reviews

There are no reviews yet.